Light Guiding Bar is a unique Light Guide

product made by Fukuvi, a professional

resin molding company.

The light guiding bar is Fukuvi's original light guiding product, made of transparent resin, that directs the light of an LED source and produces a beautiful and elegant result.

It has excellent heat resistance, flexibility, light uniformity, and can be used in a variety of applications such as automobiles, home appliances, robotics, medical equipment , etc.

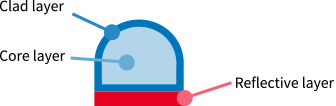

It has a two-layer structure that uses acrylic resin for the core layer and a low refractive index material for the cladding layer and uses the difference in refractive index between them to guide the light.

Uniform luminescence of up to 2.5m can be achieved. (When the light source enters from both ends, it conducts light up to 5m.)

In addition to lighting up the entire light guiding bar, it is also possible to achieve localized illumination depending on the design of the surface layer.

We offer a wide variety of thicknesses, as well as, a "hard type" and a "soft type" guiding bar, which can be mixed and matched with the offered optical characteristics and combined to meet your needs.

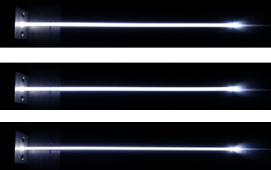

Since the light of the LED is projected as a linear light source, it is possible to create a beautiful glow along the length of the bar.

Utilizing Fukuvi Chemical's strength in profile extrusion molding technology, we can mold a variety of light guiding bars, including not only circular shapes but also complex shapes and those with reflective layers and directional light emission.

When compared to other products that aim to illuminate along a certain length, such as the more common LED tape, which requires complete replacement once an LED fails along its span, our light guiding bar utilizes only one LED light source, which is at the beginning of the line, and only the faulty light source needs to be replaced, making maintenance easier.

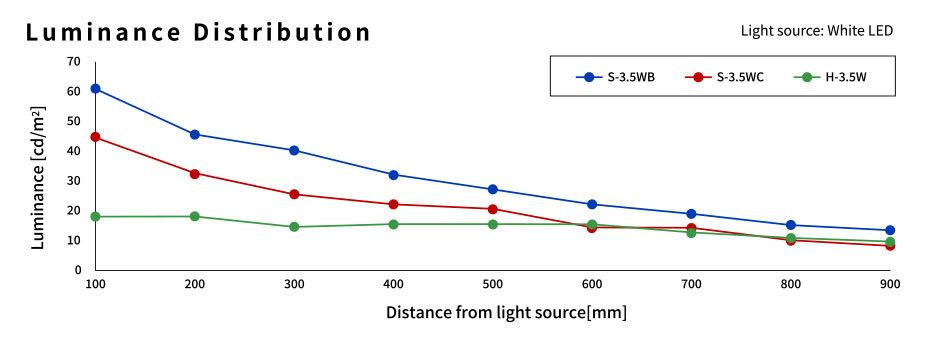

Using acrylic resin with excellent transparency as the core layer, we have developed specifications for three variants with different features.

Soft high-brightness type with excellent luminescence, flexibility and impact resistance

Soft light emission uniform type that suppresses chromaticity changes in white light and has flexibility and impact resistance

Hard type with excellent durability and light emission uniformity

By using a high performance resin for the cladding layer, excellent durability (weather resistance, chemical resistance, and stain resistance) has been achieved.

| Round Shape Appearance: White |

Outer Diameter (mm) |

S-B type | S-C type | H type |

|---|---|---|---|---|

|

F3.5 | S-3.5WB | S-3.5WC | H-3.5W |

| F4.0 | S-4.0WB | S-4.0WC | H-4.0W | |

| F6.3 | S-6.3WB | S-6.3WC | H-6.3W | |

| F8.0 | S-8.0WB | S-8.0WC | H-8.0W | |

| Reflection layer (red: reflective layer) |

Size A×B(mm) |

S-B type | S-C type | H type |

|

5.0×5.0 | S-KWB | S-KWC | H-K |

※S-B (soft high brightness) type is suitable for emitting light over short distances.

※S-C (soft uniform luminescence) type is suitable for long luminescence while having excellent flexibility.

※H (hard) type has excellent light emission uniformity.

| Heat Resistance | 85℃× 500h |

|---|---|

| Thermal Resistance | 80℃× 24 h → -30℃ × 24h |

| Moisture Resistance | ※50℃・95% × 500h |

| Cold Resistance | -30℃× 500h |

※Test conducted on a sample sealed at both ends.

No change in optical

properties for all 3 types

We have a track record of developing complex shapes and

will achieve molding according to your needs.

| Circular Shape |

Exterior Color |

Outer Diameter (mm) |

S-B type | Circular Shape |

|---|---|---|---|---|

|

White | φ2.0 | ― | 〇 |

| Irregular Shape (Function/ Other) |

Exterior Color |

Size A×B(mm) |

S-B type | S-C type |

|---|---|---|---|---|

|

White | 5.8×6.5 | 〇 | 〇 |

|

White | 30.0×3.0 | 〇 | 〇 |

Irregular| Exterior Color |

Size |

A×B(mm) H type |

|

|---|---|---|---|

|

White | 5.8×6.0 | 〇 |

|

White | 5.8×6.5 | 〇 |

|

White | 5.4×4.9 | 〇 |

|

White | 30.0×3.0 | 〇 |

| Reflective Layer Added (Red part = reflective layer) |

Exterior Color | Diameter A×B(mm) |

H type |

|---|---|---|---|

|

White | φ6.3 | 〇 |

|

White | 4.6×4.6 | 〇 |

|

White | 6.7×6.0 | 〇 |

|

White | 12.0×10.0 | 〇 |

|

White | 30.0×3.0 | 〇 |

Step illumination for domestic passenger cars

Tourist sightseeing bus ceiling illumination

Interior illumination of overseas passenger cars

Overseas Truck Illumination

Highway wire rope

Electrical appliances, etc.

It can be used not only in vehicles, but also in various applications such as home appliances, robotics, e-sports gaming chairs and peripherals, interiors, interior illumination, construction materials, etc.

Vehicle Interior Illumination

Robotics

Gaming Chairs

Household Appliances/

Electronics

Interior

Interior Illumination

Contact Us

Meeting to discuss specifications

Our representative (or engineer, as the case may be) will ask you about the details of your request and determine whether our existing product lineup can meet your needs.

Selection from our existing products

Special Order

If there is nothing in our existing lineup that matches your needs, we will create a special order. In some cases, a new mold may be required. We will provide design drawings + mold cost + product price.

Quotation

Estimate (including mold cost)

Ordering of molds - Provision of prototypes

Once the new design is decided on, the mold will be manufactured. It takes about 2 months from mold fabrication to prototype shipment.

Approval of prototype

The customer evaluates the prototype, and if it is acceptable, the initial production will be started after concluding the delivery specifications.

Ordering

Shipment and Delivery

We have developed extrusion molded products with a metal-like texture by using our original metallic tone resin. Standard and custom colors are available. Please feel free to contact us.

Lightweight, low thermal conductivity, low dew condensation, and high rust resistance.

・Commercial

refrigerators

・Construction materials

Since our founding, we have continued to support various industries and fields with resin molding technology to create new value with the power of chemistry unique to Fukuvi. We will continue to take on challenges in order to give shape to our customers' ideas. With the power of chemistry, you can give shape to your ideas.